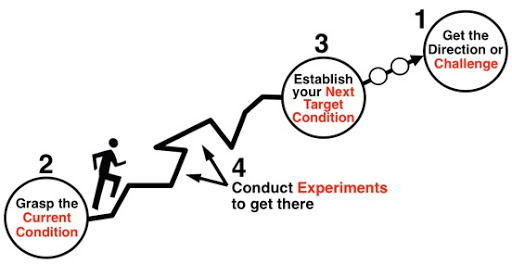

Our consultants will guide your team through the Toyota Kata continuous improvement process. We deliver meaningful solutions that lead to financial growth.

Step 1: Get the Direction

We will meet with your leadership team to understand the business goals of the improvement activity and how improvements will lead to positive future financial growth.

Step 2: Grasp the Current Condition

Our consultants will take data-driven current state assessments of what is actually happening in your business, and look for gaps in your current processes.

Step 3: Establish Target Condition

After all data is collected, we break down your larger goal into smaller chunks and achievable targets. This phase is done with buy-in from management and value-added team members.

Step 4: Conduct Experiments (PDCA)

This is where the rubber meets the road. We work together with your team to make real improvements to your business. Although it’s not always easy, we use the powerful PDCA process (Plan-Do-Check-Act) to help your team accomplish its goals.