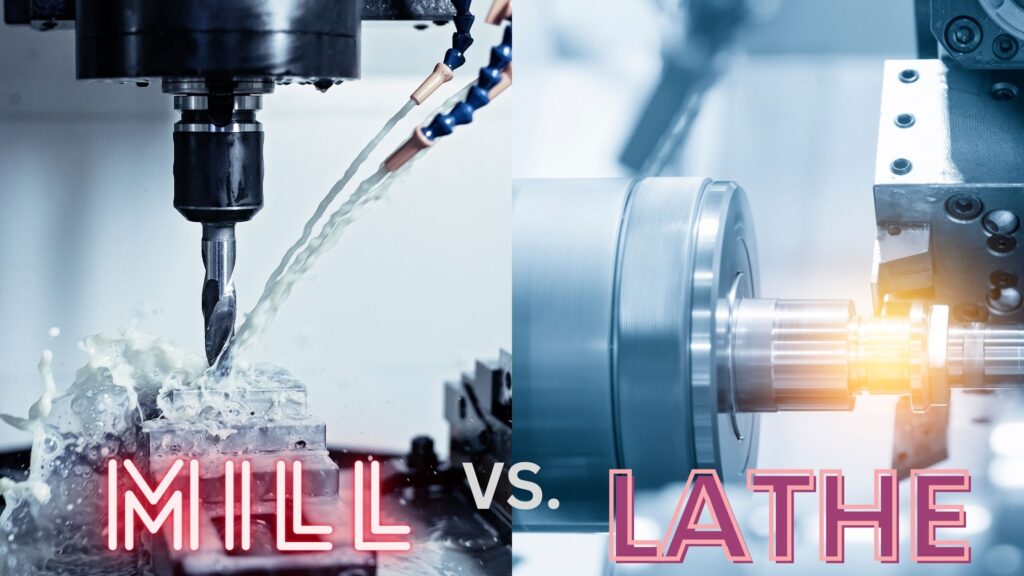

In the world of modern manufacturing, Computer Numerical Control (CNC) technology has revolutionized the way complex parts are fabricated. CNC machines, including mills and lathes, offer precise and efficient solutions for various manufacturing needs. But when do you choose a CNC mill, and when is a CNC lathe the better option? Let’s dive into the numbers to help you make an informed decision.

1. Complexity of Geometry:

CNC Mill: When the part’s design involves intricate shapes, pockets, slots, and 3D contours, a CNC mill shines. It excels at producing complex geometric features thanks to its multi-axis movement capabilities.

CNC Lathe: If your part primarily features rotational symmetry and is cylindrical or conical in shape, a CNC lathe is the way to go. It’s particularly efficient for producing shafts, threads, and other revolving components.

2. Dimensional Precision:

CNC Mill: Need high accuracy across multiple dimensions? A CNC mill offers exceptional dimensional precision. It can achieve tight tolerances and produce parts with intricate details.

CNC Lathe: When dimensional precision is crucial along the rotational axis, a CNC lathe delivers excellent results. It’s ideal for achieving precise diameters and lengths.

3. Material Removal Rate:

CNC Mill: If your priority is to remove a substantial amount of material quickly, a CNC mill is the better choice. Its cutting tools can rapidly carve out material from a solid block, making it efficient for bulk material removal.

CNC Lathe: While not as quick at material removal as a mill, a lathe is great for achieving smooth finishes on rotating parts. It’s particularly useful when maintaining a consistent diameter or achieving a mirror-like surface finish.

4. Tooling Costs:

CNC Mill: The versatility of a mill often requires a broader range of cutting tools, which can lead to higher initial tooling costs. However, these tools can be used for various projects.

CNC Lathe: Tooling costs for lathes can be lower, as the primary tools required are turning tools and a few others for specific tasks. This can make lathe operations more cost-effective for certain applications.

5. Setup Complexity:

CNC Mill: Setups can be more intricate due to the need to secure the workpiece and ensure proper alignment along multiple axes. This complexity might increase production lead times.

CNC Lathe: Setup for a lathe is generally simpler, as the workpiece is often clamped once and rotated. This streamlined setup process can lead to quicker turnaround times.

6. Batch Size:

CNC Mill: For smaller production runs and prototyping, a CNC mill is advantageous. It allows for quick adjustments and accommodates different part designs without significant setup changes.

CNC Lathe: When dealing with larger production quantities of symmetrical parts, a CNC lathe’s ability to replicate the same operation on multiple workpieces efficiently can save time and effort.

7. Versatility:

CNC Mill: The ability to work on a wide range of materials, including metals, plastics, and composites, makes CNC mills versatile for various industries.

CNC Lathe: While lathes also handle multiple materials, they excel at machining materials with rotational symmetry, making them essential for industries like automotive and aerospace.

Conclusion:

In the world of CNC machining, both mills and lathes offer unique advantages that cater to different manufacturing needs. The decision between using a CNC mill or a CNC lathe depends on factors such as part geometry, dimensional precision, material removal rate, tooling costs, setup complexity, batch size, and versatility.

By considering these numeric factors alongside your specific project requirements, you can make an informed choice that leads to efficient production and high-quality parts. Whether it’s the intricate contours of a CNC mill or the rotational precision of a CNC lathe, the numbers will guide you to the right decision.