Engineered sheet metal solutions with precision forming, cutting, and assembly oversight.

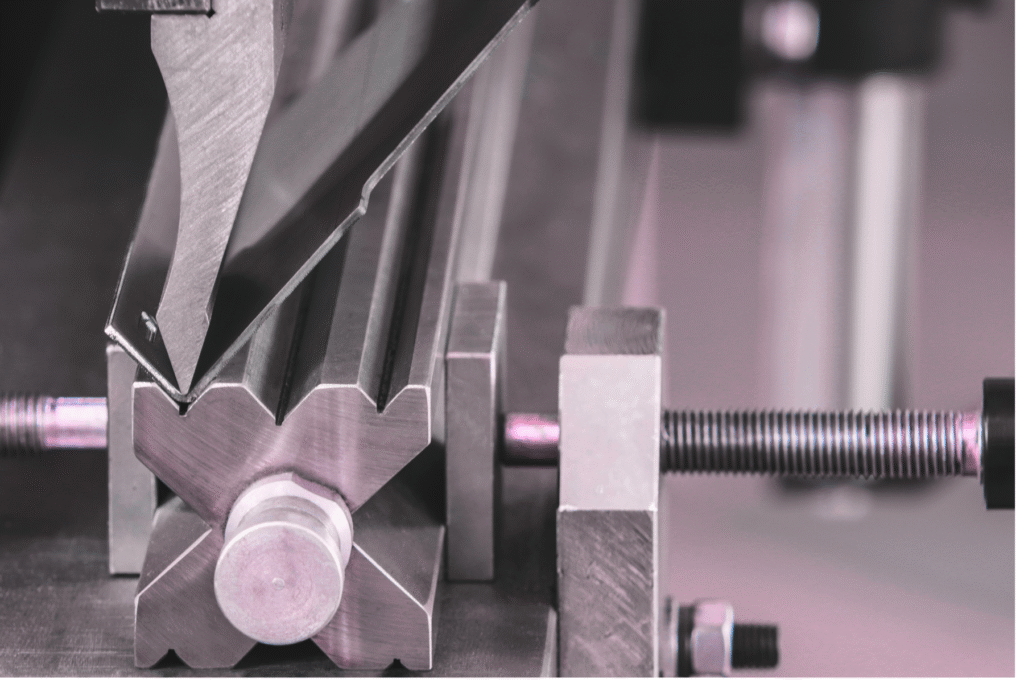

- Parts are fabricated using CNC laser cutting, punching, and bending processes to meet complex flat pattern and formed part requirements.

- Projects are reviewed for bend allowances, tolerance stacking, and material behavior to ensure parts form as intended.

- Enclosures, panels, brackets, and housings are built with consistent dimensional accuracy and smooth transitions between cut and formed features.

- Materials include aluminum, stainless steel, cold-rolled steel, and specialty alloys—sourced and specified to meet mechanical and finish requirements.

- Attention is given to hole alignment, clearance, and hardware installation to ensure seamless integration into larger assemblies.

- Finishing options such as powder coating, anodizing, or plating are coordinated as needed for appearance or corrosion resistance.

- Dimensional verification by third-party metrology can be included to confirm flatness, hole location, and form angles where critical.

- Commonly used in electrical enclosures, medical equipment, consumer products, and industrial systems.